The world has clearly put forward the slogan of “green environmental protection, energy saving and consumption reduction”, and the energy consumption of the plant is directly related to the natural ventilation and cooling system software of the steel structure workshop. The quality of the natural ventilation and cooling system software of the steel structure workshop is all natural Important indicator values for environmental considerations.

In the past, many customers told people that in summer, the temperature in the industrial factory room is higher than the outdoor temperature. If there is a production line equipment that is hot and hot, the temperature of the production workshop reaches 45-52 degrees, and the employees work in a high temperature natural environment for a long time. , the mentality is upset, and the productivity is not high, which is easy to cause employees to quit and increase safety risks.

Natural ventilation and cooling of industrial plants is a comprehensive problem. To deal with environmental quality problems, symptomatic treatment is necessary. It is necessary to find the primary conditions that endanger the temperature of steel structure workshops, mainly to rectify them, and then select suitable methods to purposefully treat the natural environment. Environmental natural ventilation and cooling are carried out to solve the problem in order to exceed the excellent natural ventilation environment. The following problems should be considered for cooling the steel structure workshop:

1. What is the fire resistance of the steel structure workshop?

2. What are the natural ventilation characteristics of the steel structure workshop?

3. Does the steel structure workshop have cooling system software?

1. The roof of the steel structure workshop is modified with thermal insulation materials to cool down

When the overall planning of the steel structure workshop is in progress, the roof modification of thermal insulation energy materials is the main consideration for the thermal insulation equipment of the steel structure workshop. The thermal insulation energy materials of the steel structure workshop can isolate most natural light radiation sources and transmit heat, reducing Global warming occurs in the room. In turn, the temperature of the industrial plant is greatly reduced, and the natural environment of the steel structure plant is improved. There are two common options today:

Insulation material for the flat roof of the steel structure workshop. Generally, the insulation material used on the flat roof is glass fiber wool, the common thickness is 50mm, 75mm, 100mm, and the relative density is 10kg/m

The installation can generally reduce the room temperature by 5-8°C. The whole process of construction is complicated. If the old industrial plant is to be renovated for thermal insulation, the original flat roof must be dismantled, the steel mesh should be pulled up, and glass should be installed on the steel mesh. Fiber cotton, cover the original color steel roof, and then do a moisture-proof solution.

The thermal insulation and reflective surface architectural coatings with the highest rate of spray paint on the color steel roofs, such products have excellent thermal insulation properties, and can be used on metal materials, concrete, gray walls, wood structure building surfaces, asbestos tiles, plastics, Various surface coatings such as FRP anticorrosion and vulcanized rubber. The coating is 0.25mm thick, and its actual effect is equal to the effect of 250px-375px glass fiber cotton. It can reflect 99.5% of infrared induction, 92.5% of invisible light, and the actual effect of maximum sound insulation and noise reduction is 68%. The average sound insulation and noise reduction actual effect About 50%, fire safety class A, completely flame retardant. Non-toxic safety, maximum durability, service life of about 15 years (for details, please refer to the construction material file); if this method is used, the construction is convenient, the original flat roof is not damaged, and the embrittlement of the flat roof can be prevented; After the construction of the project and before the construction of the project, the temperature difference on the surface of the slab is as large as 20 ℃, and the temperature difference in the room reaches 8-10 ℃, and the energy consumption of the steel structure workshop can be reduced by 30-70%.

2. Natural ventilation and cooling of steel structure workshop

Because the production and manufacturing equipment or machinery and equipment in the steel structure workshop generate a lot of heat, laser cutting, drilling, electric welding and other process processes in some assembly workshops all cause smoke, dust and odorous vapors. This heat flow and odor If the gas is not discharged immediately, it will accumulate in the industrial plant, resulting in the gas and commercial circulation, which will increase the temperature of the steel structure plant and endanger the natural environment of the steel structure plant.

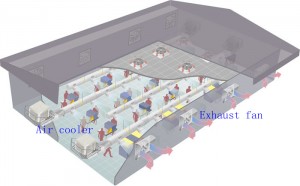

The way to deal with this problem is to ensure the effective natural ventilation of the industrial plant and install a suitable exhaust system. The installation of an effective ventilation system will significantly improve the natural environment of the industrial plant production workshop and greatly reduce the temperature of the steel structure plant.

Purposeful solution:

Installation of driving force roof forced smoke exhaust fan

The principle of Xingke exhaust fan

The principle of Xingke fan is that when the centrifugal fan is working, the gas discharged to the outside reduces the standard air pressure in the room, and the indoor air quality becomes insufficient, forming an air pressure indoor space, and the gas standard pressure difference is compensated and injected into the room. In this whole process, The windows and doors adjacent to the industrial exhaust fan are kept closed, forcing the gas to be injected into the production workshop through the window door on the side of the air inlet. The gas is lined up and injected into the production workshop from the air inlet in order, passes through the production workshop, and is discharged by the industrial exhaust fan to the production workshop. Ventilation is complete and accurate, and the ventilation rate can reach 99%.

Driving Force Mandatory Exhaust Fan Advantages:

The driving force centrifugal fan is a kind of ventilation and cooling equipment promoted by electric power engineering. Its exhaust system is easy to use and can be integrated into the natural ventilation of all natural environments. The industrial exhaust fan is used for natural ventilation on the roof and becomes a natural ventilation in the manufacturing industry to deal with high temperature, heat, smoke, odor and other natural factors in the production workshop of steel structure workshops. A strong practical effect on the problem of poor ventilation is guaranteed.

According to the special ventilation and cooling challenges of your environment, we formulate plant ventilation and cooling solutions, which can successfully maintain indoor air at a moderate temperature even in the hottest extreme natural environment to achieve the most ideal cooling Effect.

Xingke has accumulated well-known brands for 20 years, and is well-known in the ventilation and cooling manufacturing industry. The rich and diverse product production lines, extraordinary product quality, and international quality system certification can make customers feel at ease in buying and using.

Post time: Sep-21-2022