How effective is the cooling effect of the air cooler in the factory? This may be the answer that many people want to know when they have a certain understanding of air coolers used for cooling factories. Why do they ask such questions? That is because this air cooler is not better than a traditional compressor air conditioner. As closed environment can achieve constant temperature and humidity after being turned on for a period of time. The cooling effect is of course unparalleled, but the air cooler is different. It can only produce a temperature difference effect, which makes many users a little unsure. Well, if the temperature in my workshop is 38°C, how low can it drop to? What is the cooling effect? Let’s take a look together.

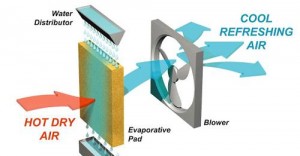

Air cooler is also called environmentally friendly air conditioner and evaporative air conditioner. It uses the principle of water evaporation to cool down. It is an energy-saving and environmentally friendly cooling air conditioner without refrigerant, compressor or copper pipe. The core component is the water cooling pad (multi-layer corrugated fiber laminate), when the air cooler is turned on and running, negative pressure will be generated in the cavity, attracting hot outside air to pass through the water cooling pad evaporator to reduce the temperature and become cool fresh air blown out from the professional air outlet to achieve the same effect. The cooling effect is achieved when the outside air temperature difference is about 5-12 degrees. When the host is running, it will continuously deliver fresh cool air to the room, forming positive air pressure to discharge the indoor air with high temperature, stuffiness, odor and turbidity to the outside to achieve ventilation, ventilation, cooling, odor removal, and reduction of toxic and harmful effects. The purpose of gas damage is to increase the oxygen content of the air; It can not only install air ducts for cooling at fixed positions to ensure the cooling effect, but can also be used in combination with industrial large fans and negative pressure fans for ventilation and cooling, regardless of Whether it is overall cooling or cooling at designated positions, the effect is particularly good, saving energy and money. Therefore, production and processing enterprises like to use air cooler equipment to ventilate and cool the factory to improve the environment.

If the temperature in the workshop is particularly high and reaches over 38°C, then the installation of air coolers can ensure that the air outlet temperature of each fixed position in the workshop reaches about 27°C. If workers in the workshop with a high temperature of 38 degrees can experience such clean cold air, The effect is naturally very comfortable and cool. Of course, some users can open doors and windows during production. If the doors and windows are opened during the use of the air cooler, the ventilation and cooling effect will be better. However, it should be noted that when choosing When purchasing industrial air cooer products, we must choose equipment with better quality, because the water curtain evaporator of the host of equipment with poor quality is of poor quality, and the air outlet may cause moisture to blow out. For some environments with relatively high production environment requirements It is easy to affect the quality of the product. Of course, if the water blows out, it will not be very comfortable for people to experience. This must be paid special attention to. There are many disputes caused by this problem in the industry.

Post time: Nov-16-2023